Dec. 27, 2022

Minerals & Metallurgy

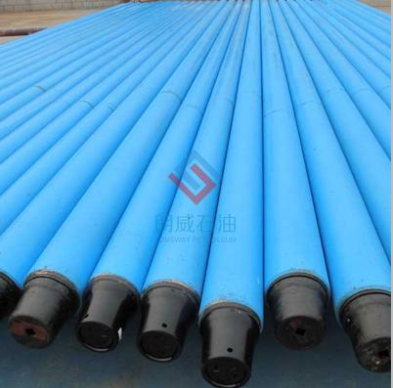

The smooth drill collar produced with international quality system certifications is the most important component of bottom hole assembly. It provides weight on the bit and offers great help to stabilize the drill and keeps it in tension. It is basically the same as that of regular drill collar, except that the outer surface is smooth and there is no spiral, no elevator.

Smooth drill collars are a type of drilling equipment used in the oil and gas industry. They are long, cylindrical pieces of equipment with a smooth outer surface and a hollow interior, and are used to add weight to the drill string in order to maintain stability and control while drilling.

Smooth drill collars are typically made from high-strength steel alloy and are designed to withstand the high pressures and temperatures encountered during drilling. They are also coated with a layer of corrosion-resistant material to protect against corrosion and erosion.

Related links:

One of the key advantages of smooth drill collars is their smooth outer surface, which reduces the drag and friction that can occur during drilling. This helps to improve the efficiency and speed of drilling operations, and also reduces wear and tear on the drill bit and other drilling equipment.

In addition to their smooth surface, smooth drill collars also have a uniform and consistent diameter, which helps to maintain the integrity of the drill string and ensures accurate measurements during drilling.

Overall, smooth drill collars are an essential piece of equipment in the oil and gas industry, and are essential for maintaining stability and control during drilling operations.

A smooth drill collar is a type of drill string component used in drilling operations in the oil and gas industry. It is a long, cylindrical piece of metal with a smooth exterior surface and is used to add weight to the bottom of the drill string. The added weight helps to apply downward pressure on the drill bit, which is necessary to break through the formation being drilled. Smooth drill collars are typically made of high-strength steel and are designed to withstand the high stresses and forces encountered during drilling operations. They are typically used in combination with other types of drill string components, such as drill pipes and heavy-weight drill pipes, to form the complete drill string.

Related links:Previous: Why Choose Galvanised Elbow Fittings for Fire Protection?

Next: What are the advantages of FRP water tank compared with steel water tank?

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )