Mar. 18, 2024

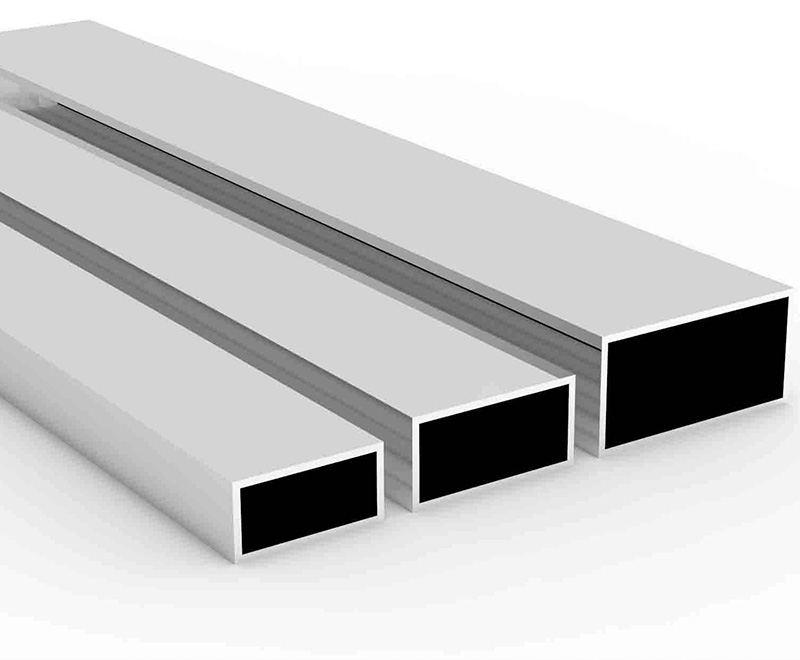

Aluminum rectangular tubing is a versatile and widely used type of hollow metal structure characterized by its rectangular cross-section. It is manufactured from aluminum, a non-ferrous metal known for its lightweight nature, excellent corrosion resistance, and high strength-to-weight ratio. This tubing finds applications across various industries, including construction, manufacturing, transportation, aerospace, and marine sectors.

Composition and Manufacturing Process

Aluminum rectangular tubing is primarily composed of aluminum alloy, which typically includes elements such as copper, magnesium, silicon, and zinc. These alloying elements impart specific properties to the aluminum, such as improved strength, machinability, and corrosion resistance.

The manufacturing process of aluminum rectangular tubing involves several steps:

Extrusion: The tubing is usually produced through extrusion, a process where a heated aluminum billet is forced through a die to create the desired shape. The rectangular cross-section is formed as the aluminum passes through the shaped opening of the extrusion die.

Heat Treatment: After extrusion, the tubing may undergo heat treatment processes to further enhance its mechanical properties, such as strength and hardness. Heat treatment methods include annealing, quenching, and aging, depending on the specific requirements of the application.

Surface Finishing: The tubing may undergo surface finishing treatments to improve its appearance and corrosion resistance. Common surface finishes for aluminum include anodizing, powder coating, painting, and polishing.

Properties and Advantages

Aluminum tube offers several advantages compared to other materials, including:

Lightweight: Aluminum is significantly lighter than steel, making rectangular tubing easier to handle, transport, and install. This property is particularly advantageous in applications where weight reduction is important, such as aerospace and automotive manufacturing.

Corrosion Resistance: Aluminum possesses natural corrosion resistance, making it suitable for outdoor and marine environments where exposure to moisture, saltwater, and harsh weather conditions is common. This resistance helps to prolong the lifespan of the tubing and maintain its structural integrity over time.

High Strength: Despite its lightweight nature, aluminum rectangular tubing exhibits high strength and durability. It can withstand heavy loads and stresses, making it suitable for structural applications where strength is essential.

Versatility: Aluminum rectangular tubing can be easily fabricated and customized to meet specific design requirements. It can be cut, welded, drilled, and shaped to create various configurations and sizes, providing flexibility in design and construction.

Thermal Conductivity: Aluminum has excellent thermal conductivity, allowing for efficient heat transfer. This property is advantageous in applications where heat dissipation or thermal management is required, such as in electronic enclosures and heat exchangers.

Recyclability: Aluminum is highly recyclable, with the ability to be melted down and reused without losing its inherent properties. This makes aluminum rectangular tubing a sustainable choice for environmentally conscious projects.

Applications

Aluminum rectangular tubing finds numerous applications across various industries, including:

Construction: Used for building frames, structural supports, architectural elements, and curtain walls in commercial and residential construction projects.

Manufacturing: Employed in machinery components, conveyor systems, frames, and structural assemblies in manufacturing facilities.

Transportation: Utilized in vehicle frames, chassis components, trailers, and cargo racks in automotive, aerospace, and marine transportation industries.

Aerospace: Used for aircraft fuselages, wings, and structural components due to its lightweight and high strength properties.

Marine: Employed in boat hulls, masts, and marine structures where corrosion resistance and durability are critical.

Decorative: Used for architectural accents, furniture frames, and interior design elements due to its aesthetic appeal and modern appearance.

Conclusion

Aluminum rectangular tubing is a versatile and durable material that offers numerous advantages across a wide range of applications. Its lightweight construction, corrosion resistance, high strength, versatility, thermal conductivity, and recyclability make it a preferred choice for structural solutions in diverse industries. With its exceptional properties and customizable features, Golden Jash aluminum rectangular tubing continues to play a crucial role in modern engineering and design projects.

Previous: How many types of aluminium profiles are there?

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )