Apr. 22, 2024

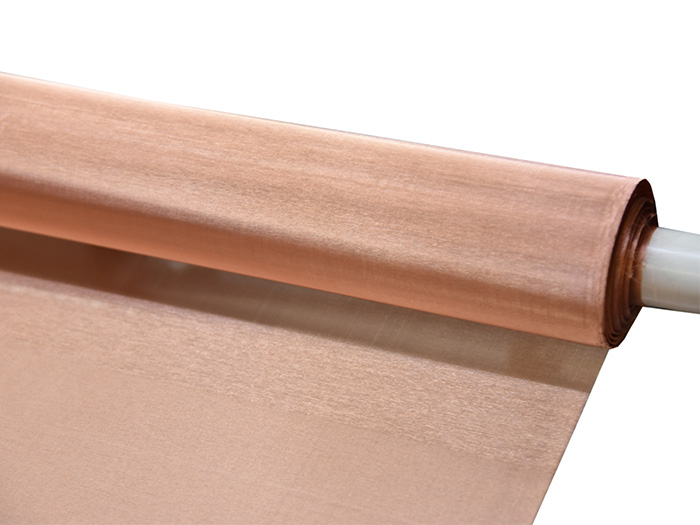

Copper wire mesh is a versatile material known for its durability, conductivity, and corrosion resistance. It finds applications in various industries, including filtration, screening, and electromagnetic shielding. As a reliable solution for diverse needs, proper installation and maintenance are crucial to ensure optimal performance and longevity.

When choosing copper wire mesh for your project, consider factors such as mesh size, wire diameter, and weave style. These specifications determine the mesh's effectiveness in fulfilling its intended purpose. Consulting with experts or suppliers can provide valuable insights into selecting the most suitable mesh for your application.

Before installing copper wire mesh, ensure that the surface or framework is clean, dry, and free from any debris or contaminants. Any irregularities in the installation surface can compromise the mesh's integrity and performance. Proper preparation sets the foundation for a successful installation process.

Use appropriate fastening methods, such as staples, nails, or screws, to secure the copper wire mesh to the desired surface. Ensure that the mesh is taut and free from wrinkles or folds, which can affect its effectiveness. Additionally, consider using edge trim or binding to prevent fraying and maintain the mesh's structural integrity.

In some cases, you may need to customize the copper mesh to fit specific dimensions or shapes. Techniques such as cutting, bending, or welding may be employed to achieve the desired configuration. Precision is key to ensuring a seamless fit and optimal functionality.

To prolong the lifespan and performance of copper wire mesh, regular maintenance is essential. Here are some key practices to incorporate into your maintenance routine:

Periodically clean the copper wire mesh using a mild detergent and water solution to remove dirt, dust, and other debris. Avoid abrasive cleaners or tools that may scratch or damage the mesh surface. After cleaning, thoroughly rinse the mesh with clean water and allow it to dry completely before reinstallation.

Regularly inspect the copper wire mesh for signs of wear, corrosion, or damage. Pay close attention to areas exposed to harsh environmental conditions or mechanical stress. Promptly address any issues to prevent further deterioration and maintain optimal performance.

Consider applying protective coatings or treatments to enhance the mesh's resistance to corrosion, oxidation, or chemical exposure. Consult with coating specialists to identify the most suitable options for your specific application requirements.

Proper installation and maintenance are critical aspects of maximizing the performance and longevity of copper wire mesh. By following the expert tips outlined above, you can ensure that your mesh operates at peak efficiency and delivers reliable results for your applications.

Previous: Titanium Woven Wire Mesh - Non Ferrous Metal Mesh

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )